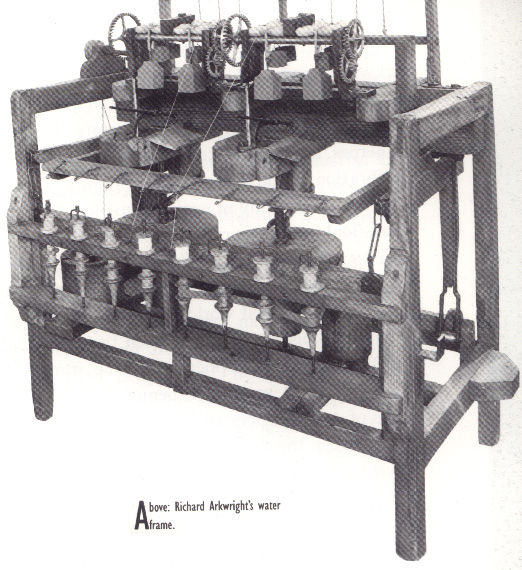

“On

Richard Arkwright’s later and more effective machines there were three

pairs of rollers, which drew out the partially spun yarn a little before the

rotation of the flyer gave it the final twist.”

“On

Richard Arkwright’s later and more effective machines there were three

pairs of rollers, which drew out the partially spun yarn a little before the

rotation of the flyer gave it the final twist.”

“failure of work discipline and organization…”

“Richard Arkwright thus became accepted as the pioneer of cotton spinning

in factories, not only because he had better machines, but also because he

was more effective at tackling the problems of discipline and organization.

“…operated on the basis of 12 hour day. Employees worked six hours

before midday meal break and six hours after….for a hundred years.”

Pacey, p. 107

"Arkwright created the first mechanization of production in 'a hostile environment without protectors, without government subsidy, but nourished by a relentless utilitarianism that feared no financial risk or danger."

Postman, p. 41.

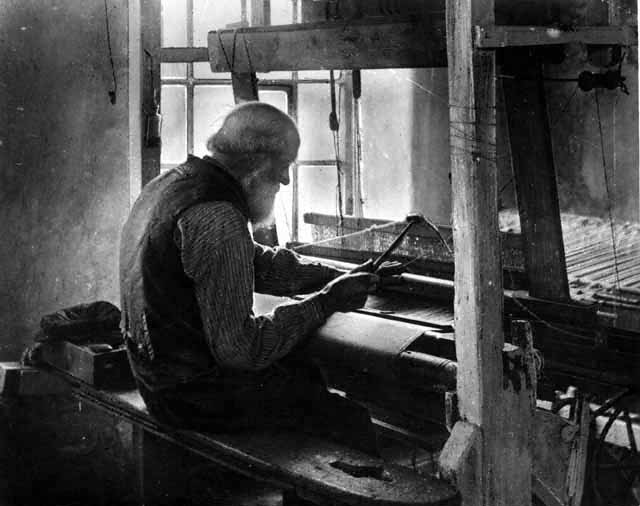

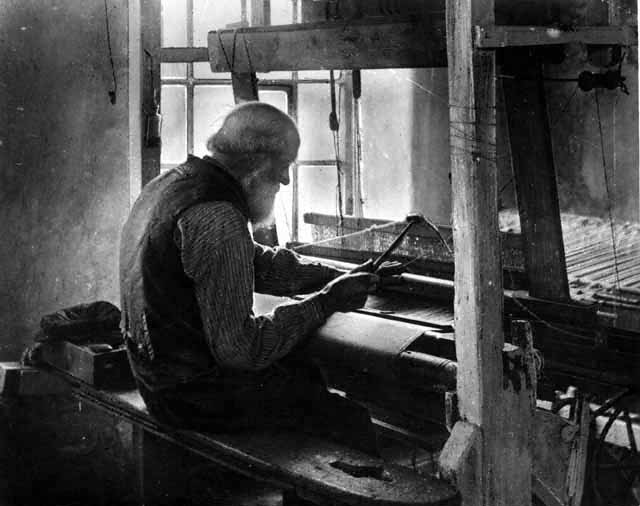

NEXT: The importance of power looms over hand looms.

The move from hand looms to power looms and the social transformation of labor and technical production.

“In any case, toward the end of the eighteenth century, technocracy was well underway, especially after Richard Arkwright, a barber by trade, developed the factory system. In his cotton spinning mill, Arkwright trained workers, mostly children, "to conform to the regular celerity of the machine', and in doing so gave an enormous boost to growth of modern forms of technocratic capitalism."

“In any case, toward the end of the eighteenth century, technocracy was well underway, especially after Richard Arkwright, a barber by trade, developed the factory system. In his cotton spinning mill, Arkwright trained workers, mostly children, "to conform to the regular celerity of the machine', and in doing so gave an enormous boost to growth of modern forms of technocratic capitalism."

Postman, p. 41.

"The new royalty was reserved for men like Richard Arkwright, whose origins were low but whose intelligence and daring soared. Those possessed of such gifts could not be denied political power."

Postman, p. 45.

"These are the men who created the twentieth century, and they achieved wealth and prestige, and power that would have amazed even Richard Arkwright."

Postman, p. 54.

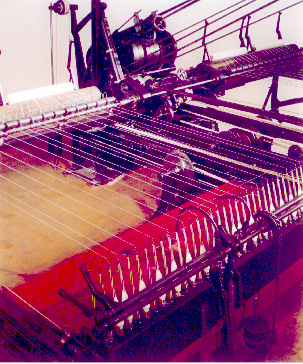

The Lowell Mills in Massachusetts [photographed below] applied water power to operate textile machinery employing women and children to operate these more 'self-acting' types of machinery that ran at high speeds and made a deafening sound when in motion. The extensive character of these buildings and the supporting structures needed to supply people, power, and raw materials to these factories transformed New England from 1798 on.

“In the manufacture of calicoes, yarn spun on Arkwright’s machines

proved suitable. Arkwright had been lobbying the government and had persuaded

it to reduce the excise duty payable on calicoes made in Britain."

p. 120.

Arnold Pacey, Technology

in World Civilization

Sir Richard Arkwright, a hair stylist and

barber was also an inventor of a device that quite transformed the means by which cloth fabric was converted from raw materials of cotton thread or wool yarn. In so doing he represents an early step toward a new level of integrated mechanization that required accompanying social changes to create an entirely unprecedented means of employment. There are many who argue that changes associated with weaving and spinning, referred to as textile manufacturing formed one of the important foundations of the industrial revolution that occurred between 1700 and 1900.

Sir Richard Arkwright, a hair stylist and

barber was also an inventor of a device that quite transformed the means by which cloth fabric was converted from raw materials of cotton thread or wool yarn. In so doing he represents an early step toward a new level of integrated mechanization that required accompanying social changes to create an entirely unprecedented means of employment. There are many who argue that changes associated with weaving and spinning, referred to as textile manufacturing formed one of the important foundations of the industrial revolution that occurred between 1700 and 1900.

A woman spins cotton fiber into thread using a discarded bicycle wheel adapted to what was a very ancient process. Before yarn or thread can be woven into fabric, the wool or cotton (silk also) must be transformed by spinning.

A woman spins cotton fiber into thread using a discarded bicycle wheel adapted to what was a very ancient process. Before yarn or thread can be woven into fabric, the wool or cotton (silk also) must be transformed by spinning.