![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Pursell quotes Herman Melville's Captain Ahab about sane motives leading to insane ends.

Because technology is by definition a means to some defined and other, often unintended, ends.

Argument | Thesis | Structure | Graphic | theme | Outline | Revolution | schism | Taylorism | method

Pursell's argument is developed in analogical form in Chapter 4.

He weaves social responses tightly into automotive industrial progression, worldwide warfare's demands, management of mass production, and newly emerging domestic arrangements that appear to contradict the very motives elevated by mechanization of tools.

Chapter four | Outline of | Key Ideas | Theme | Events

Hence he detects and insanity at the core of modern values; in that the head having absorbed the heart in a metaphorical sense, –because it can, because we have an appetite, and because we do not know what we have done–relentlessly subordinates all other values to an unrestrained and rigidly rational, yet still maladaptive logic that is mistaken for reason.

Uniformity: "A new discipline had to be devised. . . Taylorism."

Standardization or tools and behavior, fifteen minute learning.

pp. 99-104.

Three facets' diagram | Chapter four | Outline of | Key Ideas | Theme | Events

Argument | Thesis | Structure | Graphic | theme | Outline | Revolution | schism | Taylorism | method

Chapter 4, Mass production (1926) & Conspicuous consumption

Mass production "is the focusing upon a manufacturing project of the principles of power, accuracy, economy, system, continuity, speed and repetition."

p. 94.

"...of what is necessary for science, progress, modernism."

As a collective imperative [cultural ideology], however, the chill the heart."

p. 94.

The great schism of industrial production and personal meaning we call characteristic of the "modern mind."

p. 100-108.

Three facets' diagram | Chapter four | Outline of | Key Ideas | Theme | Events

Argument | Thesis | Structure | Graphic | theme | Outline | Revolution | schism | Taylorism | method

Outline of Chapter Four.

- MacDonald's dual uniformity tied to Henry Ford's automotive revolution

- The assembly line innovations (an example of exaptation)

- The largest foundry in its time–River Rouge–employed 10,000 people

- Need for workers and a new factory discipline

- Fordism, mass production drove a movement for vertical integration

- The turn to Taylor whose time & motion studies suited management

- The "utopian dream of science based labour efficiency..." or scientific management emerged, p. 100

- Shop floor control of work slowly ended

- efficiency engineer Frank Gilbreth (1868-1924)

- "increasing alienation of factory labour."

- Unionization clashed with the mass production of Fordism and Taylorism

- Utopian versus distopian novels of a new industrial era

- "The dream of social engineering led perhaps inevitably to a turn to technocracy, the rule by a technical elite." p. 112

- Japanese car manufacturing superseded Fordism and Taylorism's inherent constraints

- Mass production's offspring are numerous from MacDonald's uniformity to high speed colliders for nuclear research to reveal quarks and bosons.

p. 117

Three facets' diagram | Chapter four | Outline of | Key Ideas | Theme | Events

Argument | Thesis | Structure | Graphic | theme | Outline | Revolution | schism | Taylorism | method

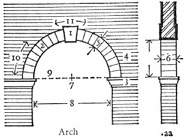

An example of technology's three facets applied to automotive production.

| Automobiles | ||

|---|---|---|

|

||

| Ideological responses | Social & Organizational responses | |

|

||

Go here to compare the above diagram.

Three facets' diagram | Chapter four | Outline of | Key Ideas | Theme | Events

Argument | Thesis | Structure | Graphic | theme | Outline | Revolution | schism | Taylorism | method

World War One was called the Great War, 1914-1918;

WWI impact & demands changed society and widespread beliefs

1893 – seeds of the automated war were sown in two prior decades

Boer Wars, 1880-81, & 1899-1902.

automatic weapons & the machinery of war

scorched earth policy targeting civilians

British created concentration camps for Boers, Dutch descendants

The increasing intensity of World War I slowed the Gilbreth's work overseas.

Three facets' diagram | Chapter four | Outline of | Key Ideas | Theme | Events

Chapter four introduces themes of insanity, speed, alienation, unification of the division of labor, and mental schizophrenia that were introduced in chapter three and will be developed coherently again in chapter five.

| Structure of the book: | ||

Power | Standardization | Taylorism | Schism | Society | Materials | Information | Knowing | Labor

Macdonald's employees as examples of the impact of precision, uniformity, and speed on the training and behavior of unskilled and semi-skilled labor.

How the mass production in automobiles replaced hand crafted cars after 1915.

Edward Ellis M.P. and the odyssey of his 1894 purchase of an automotive vehicle in France to use in Britain.

Speed limits and distances he traveled at ten miles per hour in his new car.

Skilled craftsmen and the role of piece-by-piece hand assembly of cars.

How the Ellis experience is contrasted with Henry Ford's manufacture and his complete changes by employing (at least superficially) mass production.

94-9.

Ford 1913-1914 was a revolution in techniques that affected labor organization

98.

Frederick Winslow Taylor's Principles of Scientific Management, 1911,"his utopian dream of a science-based labour efficiency" and then when tied to Ford's adaptation of the assembly line means to a mass produced commercially viable product led to "the single largest and most integrated production plant in existence."

99.

"Ford vertically integrated his operations.…"

1913 The Highland Park plant experienced one in ten workers sick each day and example of pre-industrial expectations.

100.

To see the impacts today, see Simon Head, Mindless.

Three facets' diagram | Chapter four | Outline of | Key Ideas | Theme | Events

Argument | Thesis | Structure | Graphic | theme | Outline | Revolution | schism | Taylorism | method

The Automotive revolution

Exaptation from the meat packing industry of the means by which cars -- like carcasses were brought to the worker's assembly stations from overhead (automated) delivery systems.

The River Rouge Plant

10,000 workers building cars by assembly line production

Mass production, Taylorism, scale, rigid division of labor, and the immediate result was productive outcomes in the form of more cars, made less expensively and with workers making five dollars a day in wages.

99.

The First World War, 1914-1918.

A devastating and complete transformation of world affairs, social behavior and collapse of cultural customs that undermined European empires and hegemony.

The revolution came in social, economic, cultural, and political values.

1912, Taylor's book and the influences on management of Frank and Lillian Gilbreth's time and motion studies.

104.

Pursell detects that the hyperbole of scientifically driven progress and the promise of rational management did not correspond well with the reality in that the imagery of the happy home-maker was at odds with the grim and often mindless reality of alienation experienced by line workers at the factory in the 1917-1937 period.

1935 Lillian Gilbreth's address on the "home efficiency movement."

"Food planning in the Home to ensure satisfactory nutrition with a minimum expenditure of time, money, and labour."

105.

Three facets' diagram | Chapter four | Outline of | Key Ideas | Theme | Events

Argument | Thesis | Structure | Graphic | theme | Outline | Revolution | schism | Taylorism | method

Ford's automobile assembly line for mass production and related labor innovations in 1914 were slowly transferable (diffusion) to Russia, Britain in 1929, and Italy in 1936 with respect to mass production.

But re-industrializing Germany in the 1933 and decade after was the best application of his means to increase production that brought down the price of cars.

107.

J. B. Priestly observed

"men came first, machines after."

108.

The Great War, the real test of Taylorism and political upheaval–1917 the Russian Czarist Monarchy was replaced by the Mensheviks and later the Bolsheviks two factions of Communists after 1905 and 1917.

Revolution in Germany 1919, led to the creation of the Weimar Republic after then Communist uprising was defeated.

Marinnetti's futurists were an indicator of political mutation of continental European industrialization not seen in England until the 1926 General Strike of organized labor against corporate elites.

Note: The United Kingdom's General Strike lasted nine days, from 4 May to 13 May 1926.

110.

Three facets' diagram | Chapter four | Outline of | Key Ideas | Theme | Events

Argument | Thesis | Structure | Graphic | theme | Outline | Revolution | schism | Taylorism | method

The declaration of the Futurists

1909 Manifesto by F. T. Marinetti

"We wish to glorify War–the only health giver of the world– militarism, patriotism, . . . the beautiful Ideas that kill…."

110.

"We shall sing of the great crowds in the excitement of labour, pleasure and rebellion…."

111.

Fritz Lang's Metropolis was a revolutionary film showing the dispensable character of the industrially skilled workers.

111.

Taylorism had the impression of political neutrality, but the power to organize work was and is a political act according to Pursell.

"The Lang film and the Krupp's filial piety echoed the already obvious Nazi commitment to efficiency and romanticism and epitomized the kernel of irrationality at the heart of Ford and Taylor's miracle."

"inevitably to a turn to technocracy"

112.

Robot was the Czech word for servile worker and was made into a cornerstone of critical literature (a play) against the role of the new machinery in turning workers into machines.

113.

The impact of industrialization on cultural motifs & social relations:

Challenge to Ford's standard model production by,

Alfred P. Sloan at GM and planned obsolescence, the yearly model change, and consumer credit (GMAC)

115.

mass markets ended up in promoting monoculture crops due to the demand for fast food and beverages.

"the offspring of mass production are numerous and varied. Agriculture reduced to monoculture, with goals of replacing natural processes and products with more readily controlled 'scientific' substitutes (chemical fertilizers for manures, genetically redesigned mammals), is one example."

The dates in Brave New World were based on BF and AF standing for Before Ford and After Ford, as a parody on Before Christ, BC, and After Christ, AD.

117.

One can discern from these examples in the chapter that the automobile and its mass production was as revolutionary as the impact of the war, on society, our behavior and imaginations.

Three facets' diagram | Chapter four | Outline of | Key Ideas | Theme | Events

Argument | Thesis | Structure | Graphic | theme | Outline | Revolution | schism | Taylorism | method

Division of labor is ancient and manufacture is medieval, with the coming of industrial production the necessity became:

- Interchangeable parts \

- Case Study, automotive engineering

- Mechanization of time /

Technicians’ roles peaked influencing invention with emergence of civil engineering but had its take-off in time and motion studies by Gilbreth's and Taylor.

Industrial organization of railways, automotive production, and electricity brought with it an organization of labor.

This social movement was called trade unionism of craft skilled laborers

and as opposed to:

industrial unions for semi-skilled and unskilled labor to bargain for working conditions, working hours, wages, and benefits.

Pursell draws a distinction between both the "human element of production," and the means of industrial routines.

p. 100.

Technological Fixes such as the automobile starterand

Standardization which solves other sorts of technical problems

“Driver’s Side” culture overrides technical considerations

Driving on the left as opposed to right side of a road

Sequencing – refers to when something is invented and thereafter applied more widely

The time between invention, testing, application and adoption often differs widely:

Too early

Too late

Both are risks of standardization

BETA vs. VHS early actionChunnel – The Channel Tunnel requires driving and drivers to shift from one side of the road to another – English (UK) Left to French (European) Right hand side of the road.

But driving changes in France to right hand side driving as in Europe & United States.USA

Close up

Scientific managementScientific development & technological improvements are less rational than they appear to be

Electrical – industry

Clearly science-based

Shop floor practices helped telegraph industry:p. 138-39.

Three facets' diagram | Chapter four | Outline of | Key Ideas | Theme | Events

Details of Taylor's Scientific Management approach:

“Hand made" is replaced by automated machinery based on the social or behavioral control of work called "Taylorism" and such a shift from making things by hand and making things by machines may well have undermined innovation.

Socio-technic changes (Taylorism and Fordism) were powerful auxiliary forces that not only accompanied but may have shaped tectonic shifts to machinery with moving parts from hand tools with few or no moving parts.

Evelyn Ellis purchase of a car -- automobile in 1894 from France is a story of hand crafted imprecision and precision born of craft and hand tools.

The Automotive revolution will replace hand assembled cars by 1916, 1929, and 1936 worldwide.

pp. 94-92, 105-107.

Be careful of the limitations of single focus thinking.

"The shop-floor control of work."

p. 103.

Because a split is widening between practices & intentions or ideas as a response to industrial mass production, work has made workers more individually powerful in the sense of production, but less powerful in the sense of control over the production process, the affordability of the products and future decisions about productivity innovations.

Three facets' diagram | Chapter four | Outline of | Key Ideas | Theme | Events

|

|

|

| Step Right Up | Welcome to the Club | Makes No Sense |

| "An effort to perfect the world through rational action." | "Standardization is the solution of last resort, an admission that we cannot solve the problem in any other way." | Uniformity: "A new discipline had to be devised. . . Taylorism." |

p. 77. |

p.137. | pp. 99-104. |

Three facets' diagram | Chapter four | Outline of | Key Ideas | Theme | Events

Argument | Thesis | Structure | Graphic | theme | Outline | Revolution | schism | Taylorism | method

From Herman Melville's' novel ( fiction based on a non-fiction, or actual event ) Moby Dick,(1851);

comes the story of a whaling ship out of New Bedford bound for ignominy in the South Pacific ocean.

"All my means are sane, my motive and my object mad."

Herman Melville, Moby Dick (1964), page 318, quoted in White Heat, p.93.

Three facets' diagram | Chapter four | Outline of | Key Ideas | Theme | Events

|

||

|---|---|---|

| Tools of Toil: what to read. | ||

| Tools are historical building blocks of technology. | ||

Authors:

Pursell | Pacey–World | Postman | Head | Tenner |Pacey–meaning| Eberhart | Snow | Kaku | Boulding | Delillo | Kranzberg

This page is was from September 29, 2007, revised September 29, 2014 .

.gif)