Navigating the site:

Research on this subject.

Selected parts of the steam engine.

| The Newcomen Engine | Watt's condensing Engine | |

|

|

|

| 18th century | 19th century | |

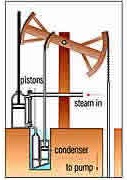

| The differences between these two steam driven machines is subtle and not quite obvious, but the one on the right displays Watt's improvement over the earlier device [on the left]. Watt's is remarkable for its precision and increase in force. It was to have revolutionized the world because of its versatility, relative ease of repair, fuel, and efficiency. | ||

![]()

Harnessing the power of steam marked a significant step in technology.

Early in the Eighteenth Century the widespread introduction of the steam engine for the drainage of deep mines moved slowly. Not until improvements were made did these more versatile engines accelerate many new inventions, most notably in transportation and industry.

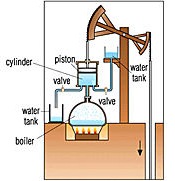

Steam engines transfer the energy of heat into mechanical energy, often by allowing steam to expand in a cylinder equipped with a movable piston. In the Newcomen engine as the piston moves up and down a chain tied to an attached arm converts this motion vertical motion to a pump. Models of the steam engine were designed as early as 1690, in France, but Thomas Newcomen built a steam engine with a counter weight to drag the arm up and down and link that to a water pump.

The parts and actions of the Newcomen steam engine.

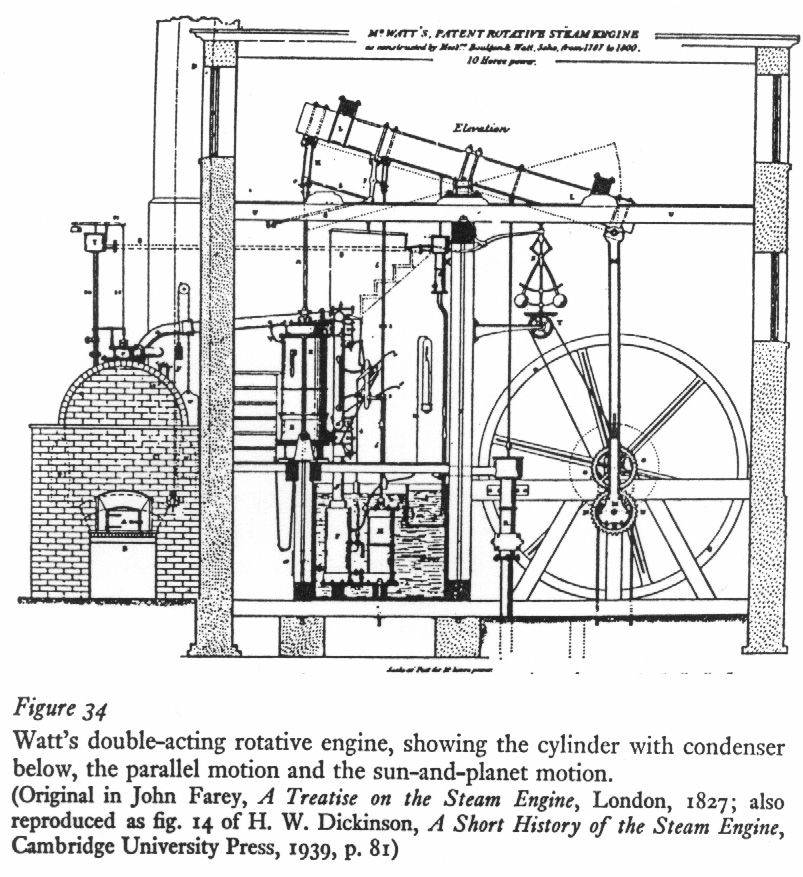

A labeled schematic diagram of a typical single cylinder, simple expansion, double-acting high pressure steam engine.

A labeled schematic diagram of a typical single cylinder, simple expansion, double-acting high pressure steam engine.

As the piston moves up and down (or alternatively, from side to side), an attached arm converts this motion into parallel motion that drives a wheel. Models of the steam engine were designed as early as 1690, but it was not until 70 years later that James Watt arrived at the design of the modern steam engine.

What is the driver of the mechanical forces?

Water boiled into steam under pressure is the source of enormous expansive power that requires a strong metal to withstand the force of the boiling water.

Motion, or driving power, is taken off from the moving engine by way of a belt attached to the crankshaft. This is opposed to a chain as was the case in the vertical steam engine that Thomas Newcomen constructed in the early 18th century to pump water from the deep mine shafts. It was that engine that James Watt had improved upon over Newcomen's earlier design.

1 - Piston [cylinder]

2 - Piston rod

3 - Crosshead bearing

4 - Connecting rod

5 - Crankshaft

6 - Eccentric valve motion

7 - Flywheel

8 - Sliding valve [valve chest]

9 - Centrifugal governor

10 - Cistern

11 - Beam

12 - Air pump

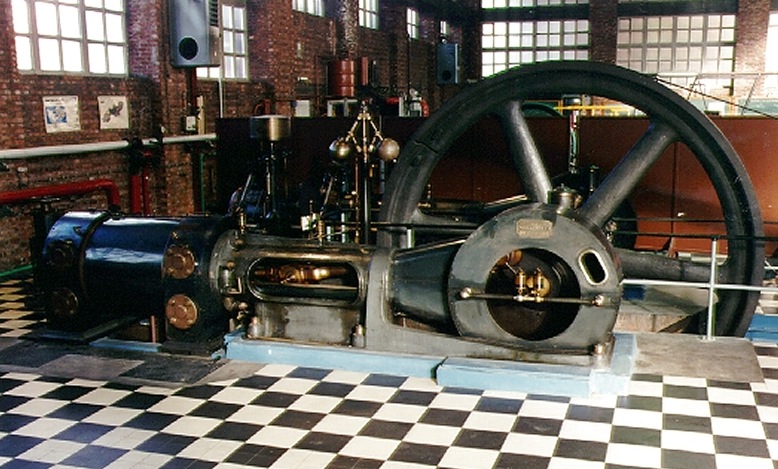

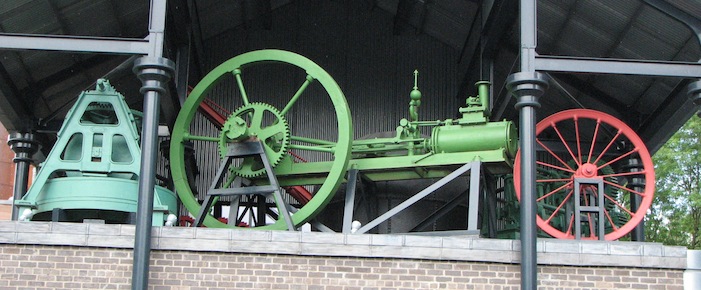

The double-acting and condensing steam engine in a horizontal configuration.

Don't know what you are seeing in the picture?

In the picture above, we see a single cylinder, with the style of valve gear present on our engine. The steam is piped into the steam chest (shown cut open), and will flow thru any uncovered steam inlet ports, in that picture, the bottom one. It will flow thru the passageway, and into the cylinder. At the same time, the top inlet is connected to the exhaust port. With the valve in the position drawn, the piston is being pushed to the top of the cylinder.

![]()

Here are some steam engine terminology and basic operational details.

Basic plan | Types of engines | Multiple cylinders | Efficient power.

Any steam engine has a piston that moves back and forth when pressure is applied, and valves to control the intake and exhaust of the contents of the cylinder. Unlike an internal combustion engine that we find in automobiles and trucks, air and fuel are drawn in; they are exploded, and this explosive force moves the piston through the cylinder (like the cannon barrel), with sufficient force to push on the piston trying to escape. In a steam engine, the inlet valve opens, and steam under pressure pushes on the piston, until you open the exhaust valve to let it out.

While they both have a piston moving in a cylinder, valves, and a crankshaft, there are a lot of detail differences between the steam engine and the internal combustion engine. While steam engines can be quite simple, most have more parts than a comparable internal combustion (IC for short) engine.

Double Acting: A piston engine that uses both sides of its pistons for the production of power.

One other difference with normal internal combustion engines is the use of a "double acting" engine. By sealing both ends of the cylinder, we can push it both directions, and provide two times or double the power of a single cylinder steam engine. All it needs is an extra seal, and space for a somewhat taller (or longer for horizontal cylinders) engine. The engine we found was double acting. While it is possible to make a double acting internal combustion engine, (the 19th century Merry engine is such a machine) the higher speeds, temperatures, and pressures that get you efficiency and power in a modern IC engine mean that there are no recent examples.

- Multiple cylinder engine: Any engine with more than one cylinder. Multiple cylinders can eliminate dead spots when starting, and reduce vibration when operating

- Simple engine: An engine where all cylinders are fed steam directly from the boiler.

- Compound engine: A multiple cylinder engine that uses the cylinders in series to expand the working fluid in stages. The exhaust of the first cylinder is fed to a second cylinder, for further energy recovery.

Steam engines can have more than one cylinder, just like an IC engine. They come in two basic styles, multiple identical cylinders all fed directly from the boiler, and the series connected "double expansion", or more generally a "compound" engine. As mentioned above, the steam exhausted from the cylinder is still at possibly significant pressure. If you dump this to the atmosphere, you throw away a lot of energy, and with it, fuel efficiency.

To get this energy back, you need to give it some confined place to expand in, and something to push against. So you add another piston, and feed it this previously waste steam. The second stage lets you capture the energy as it expands further.

Again, this is not the same as a multiple cylinder engine, they feed the same full pressure steam to all the cylinders. Without compounding, multi-cylinder engines are no more efficient than a single cylinder engine of comparable capacity.

Dorling Cinderella

With the cylinders connected out of phase, the engine can be counted on to start no matter what the crankshaft position. Most railroad engines are of this style. (multiple cylinder, single stage).

Since the second cylinder of a compound is operating at lower pressures, they are normally much larger than the cylinder in the high-pressure stage. If they are correctly scaled, power output per cylinder is comparable, which helps it run smoothly. The engine used by the Beach Boys was of this type. The higher the steam pressure, the more stages you can make good use of. I have seen some triple expansion engines, and assume that someone has tried a 4-stage engine (if not five or even more stages).

Our engine choice: A compound engine would recover more of our steam energy, but as a compound it could have the same starting problems that a single cylinder engine has. (a "dead spot" when the piston is at the top of its stroke). However, with an appropriate bypass valve in the right place, a compound engine can act like a multi-cylinder "simple" engine, (able to start in any crankshaft position).

All steam engines require fuel and wood, gas, or coal fuels when combusted produce carbon dioxide as a waste by-product. But the direct burning of fossil fuels for power in the internal combustion engine –while yielding greater power per unit of fuel– produced far greater amounts of carbon dioxide from the high temperatures and fuel choice. Coal is the most polluting, oil is next and natural gas less with respect to tons of carbon dioxide vapor added to the atmosphere and oceans. Had we stayed with steam powered engines, the levels of accumulation carbon dioxide vapor-gas in the air would have been far less.

. Accumulating carbon dioxide is a problem.

|

||

|---|---|---|

| Tools of Toil: what to read. | ||

| Tools are historical building blocks of technology. | ||