Complex

Complex Navigating the site:

![]()

Three Key Points: first | second | third | conjoin the parts? | contingent character | 2 lessons

![]()

overview | key devices | tool making | specialization in tools | origins of automation | emergent complex

No tool exists in isolation from other tools, their users, their societies, or the imaginations of people who comprehend the potential uses of technical equipment.

Techniques are critically important means of linking the worker or tool user to the implement they devise or utilize to achieve their desired end or purpose.

But in a very literal sense, tools that are at the core of the study of technology, are tied to other inventions, devices, utensils, products, patterns of wealth, implements and instruments in a systemic manner.

Social relations are so influenced my the use of and production of technological products that many forms of social organization could not exist without technology.

In addition to altering the perception of reality, technology may actually recreate social reality, in both anticipated and unanticipated ways.

In Arnold Pacey on pages 3 & 4, 9,11, and 14 there are drawings and maps for you to better picture a complex of tools.

As he reminds yo the reader on page 19:

"but for the moment our example is eleventh century China. Here there were Government institutions, independence entrepreneurs and Buddhist Monasteries all playing a part, notably in metalworking techniques and and in the development of printing."

Pacey, Technology and World Civilization, p. 19. All authors.

Keystone tools:

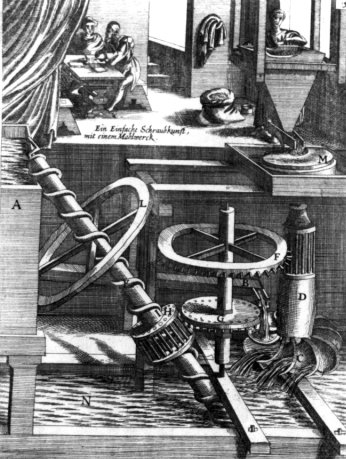

The diagram below is of a water lifting device called the Archimedean screw, named for the alleged inventor Archimedes.

Even in the drawing one sees a relation among gears, blades, curled pipes, and chutes to divert water. The use of water as a motive source and the need to move the water requires the proper sequential and calibrated application of many related tools – such connected devices form a basic part of a tool complex.

The associated devices in the above diagram of a tool complex are only one facet of a tool complex. In addition to the above relation of wooden and metal gears, cog-wheels, pipes and reservoirs, any tool complex includes the inventive and maintenance work of unskilled and skilled crafts people to keep the tools repaired and parts replaced to operate effectively.

Roman examples: roads & architecture

overview | key devices | tool making | specialization in tools | origins of automation | emergent complex

A second facet of any tool complex are the people who make, maintain, or use the devices.

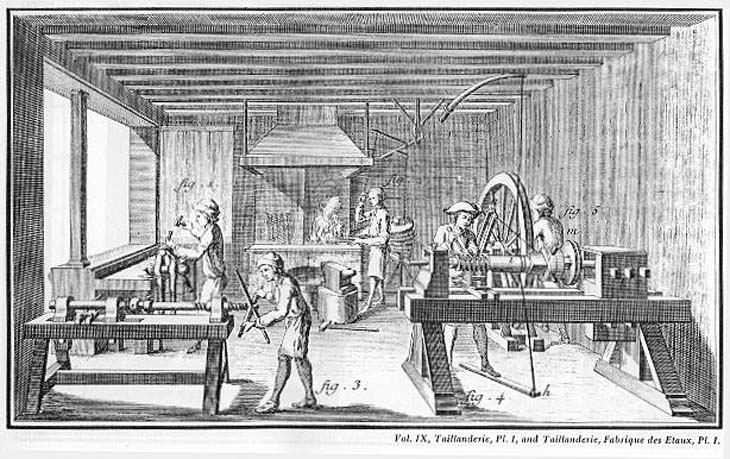

The exercise for labor is the obvious and evident feature of this depiction of workers in the manufacture of screws from the smith at the furnace in the background to the operators of the lathes to make the screws in the foreground.

This plate from Diderot's Encyclopedia in the 18th Century, reveals clearly the way in which skilled people, materials and machinery are brought together in one place then called a factory – to manufacture important devices used in the making of other useful machinery.

A process: manufacture meaning made with the hands meant hand assembled using tools; pictured here is a workshop displaying five workers at sequential stages in the assembly where a forge is used for making implements to make other tools.

Taillanderie* is a blacksmith who makes specialty tools, for certain trades; precision tools such as scissors, lanterns, or knives.

Compare the above Taillanderie to this depiction of a bakers workshop.

Because the steps in this process must be done in a sequence, the study of technology must be seen as a systematically related series of contingent steps in an entire functional sequence for the purpose of accomplishing some task or reaching a desired end.

Because the steps in this process must be done in a sequence, the study of technology must be seen as a systematically related series of contingent steps in an entire functional sequence for the purpose of accomplishing some task or reaching a desired end.

Tool complexes reveal how life for people is different depending on their skill, occupation, period in which they live and location.

What was it like for an average Roman person's life.

![]()

Implements, devices, instruments and machinery, or more; what makes up any technology?

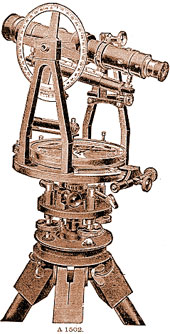

Consequences of survey instruments in USA. -----...--Surveyor's instrument,

When you look at any invention, or material object, or product of technology, you suddenly recognize that it is connected in a very precise and causal manner to related objects on which the tools and the technicians depend. As for those who make or use the tools that are brought together to accomplish some task, the connections are crucial to describe, because tools together give technology the power to accomplish specified tasks. In the example above the impossibility of straight line over any long-distance as a means of measuring property boundaries across terrain was impossible before the invention of the surveyor's instruments where the land is varied by contours and natural features such as hills, lakes, marshes, and rivers. These surveyor's instruments were only widely employed as devices for surveying land only after the late eighteenth century and early nineteenth century.

But their effective use of tools–such as the surveyor's instruments – in the service of solving a problem or producing an effect requires the skillful operation, based on a knowledge of materials and the tool's capabilities. For any tool complex to operate well over a long period of time people must know how it works, to repair, maintain, or alter its applications to fit new conditions. This increasing need to knowledge of specific applied skills was particularly true of new technology and technological changes that occurred after the domestication of fire, plants, and animals that precipitated the inventions of agriculture and mining.

Both order and informed responses to new designs were necessary for agriculture and mining to suffice the needs of societies that flourished and depended on these twin tool complexes of fire, smelting and agricultural developments in the Neolithic and later periods.

A third facet in any tool complex is the imaginative, but deliberate familiarity, tacit knowledge and experience that are derived from working with all of the parts of the complex arrangements of associated mechanisms, parts, and their effects or purpose.

overview | key devices | tool making | specialization in tools | origins of automation | emergent complex

| The tool complex, | |||

|---|---|---|---|

| is a means to envision how | |||

| users | |||

| materials | builders | ||

| create a interdependent group | |||

| that, is also a way to understand the association of similar techniques and tools brought together to create technology based on at least, if not more, than four contributing factors: | |||

|

|||

Aymaran (Amerindians from the Andes) boat builders from Lake Titicaca in Bolivia. [photograph, 1992, JVS.] |

|||

The above boat weavers need reeds that grow along the shores of Lake Titicaca high in the Andes. Their skill and knowledge of materials, production teams and organization of labor to acquire and repair the boats are all examples of --albeit a small one-- a tool complex based entirely on nature, human labor and a means of harvesting fish or transporting supplies along the lake.

LESSONS

Two lessons are: First the contingent consequences based on how the tool is put together and the lag in society is the Second lesson about how the technical complex forces adjustments in the existing processes of production.

Steam engines are examples of the complex:

Like this sophisticated steam engine with its parts labeled in the above diagram, every tool complex is distinguished from other complexes in relation to 1) tools used specific to the task, 2) the related materials required by the application of technical equipment 3) the precision steps or protocols required by the tools for them to be used safely and effectively, 4) the level attained (see list) with respect to materials, techniques, precision and desired outcomes:

- agriculture

- iron making

- steam engines

- railroads

- electrical delivery

- weaponry

- computers, electronics and telecommunications

- nanotechnology

- the power of steam operated machinery

.gif) Any tool complex is specific to an age, place and set of conditions that must be described in relation to the resources available, food items, material culture, and the level of wealth.

Any tool complex is specific to an age, place and set of conditions that must be described in relation to the resources available, food items, material culture, and the level of wealth.

Metamorphosis in three spheres of human life occurs as the tool complex is altered over time:

- landscape changes

- labor alterations due to changes in materials, hardware, or uses.

- Morality and the application of tools to solve problems.

The examples on this page of reed boat builders, water driven mills and lifting devices, screw makers and the steam engine are all examples of different tool complexes and the requirements of each complex in achieving the desired outcomes for each society will dictate the landscape changes, labor conditions and habits of mind and behavior that people who use these tools–or depend on these tool complexes will develop over time.

The subsequent lesson is that by

Reflecting on tools we can discern

Three facets of technology may often account for both the spread and the resistance to the spread of new techniques. How new material means of making products frequently succeeds in creating resistance to the impact of new devices is called a "blocked technical system."

Often one or more of these three influential aspects of tools and tool complexes can be seen as the reason why a new means of production fails or succeeds in becoming widely adopted by crafts people, machine tool operators, or technicians.

Each of the three facets contributes to either an acceptance or rejection of the newly acquired techniques derived from:

1. All the associated hardware that effects a desired outcome.

2. Skills of workers & repair teams to operate complexes.

3. A practice shifting from existing procedures and complexes to altered conditions to meet new demands, conditions, or constraints.All of these successful uses of tool complexes may create–

Social lag due to cultural drag, especially with respect to gender in the workplace or marketplace.

A data processor from the 1970s.

overview | key devices | tool making | specialization in tools | origins of automation | emergent complex

As automation made the distinguishing characteristics of men and women, less and less relevant to the operation of automated machinery (telephones, telegraph, radio, and computers, for example) the older distinctions between women's work and men's work largely disappeared. But that did not happen until certain features of these older gender distinctions were made into obstacles to keep women out of certain occupations. For example, women could be

seamstresses or dressmakers, but not a tailor. Waiters were distinguished from waitresses. It was argued that women could not operate heavy machinery, nor could they fly airplanes.

Despite the power of the tools and the tool complexes to diminish these gender based restrictions on who can and cannot use machinery, the cultural facet of technology's many dimensions seemed –for a time– resistant to these prejudices that suggested only men could be fire fighters, electricians, plumbers, carpenters, or chefs.

Some cultures are slower than others to change, women in Arabia, for example are not permitted to drive automobiles. On a less gender related example of the power of culture to shape a tool complex, the French drive on a different side of the road from the British. In both cases the automobile as a tool complex has the same materials used, components,means of manufacture and capacity to alter social conditions but cultural differences dictate a social lag with respect to women in Saudi Arabia and a cultural drag between Continental and British driving habits that have nothing to do with he machinery, tools or tool complexes.

The taillandier is a blacksmith specialized in the making of sharp tools for the cloth industry. He works for many craftsmen the such butchers or carpenters, cooks.

There existed various specialties:

• taillandiers in white works: manufacture cutting tools not acting as weapons.

• coarse taillandiers: kitchen utensils (trip hammers, toothed racks.) & large tools manufacture (shovels, fire-axes or hammers.)

• the taillandiers auger smiths (gimlets, crankshafts) and tailors of files, punches or scissors.

• tinplate taillandiers and black: specialized in the manufacture of lanterns, funnels, moulds.

Steam engine-railway industrial complex Powerful steam engines were modified to move drive wheels of what became known as the locomotive

on railroads and railways were the industry that changed the modern world

ushering in standardization, interchangeable parts, iron smelting, electricity, industrialization, finance, bureaucracy, unionization, and automation.overview | key devices | tool making | specialization in tools | origins of automation | emergent complex

Tools of Toil: what to read. Tools are historical building blocks of technology.